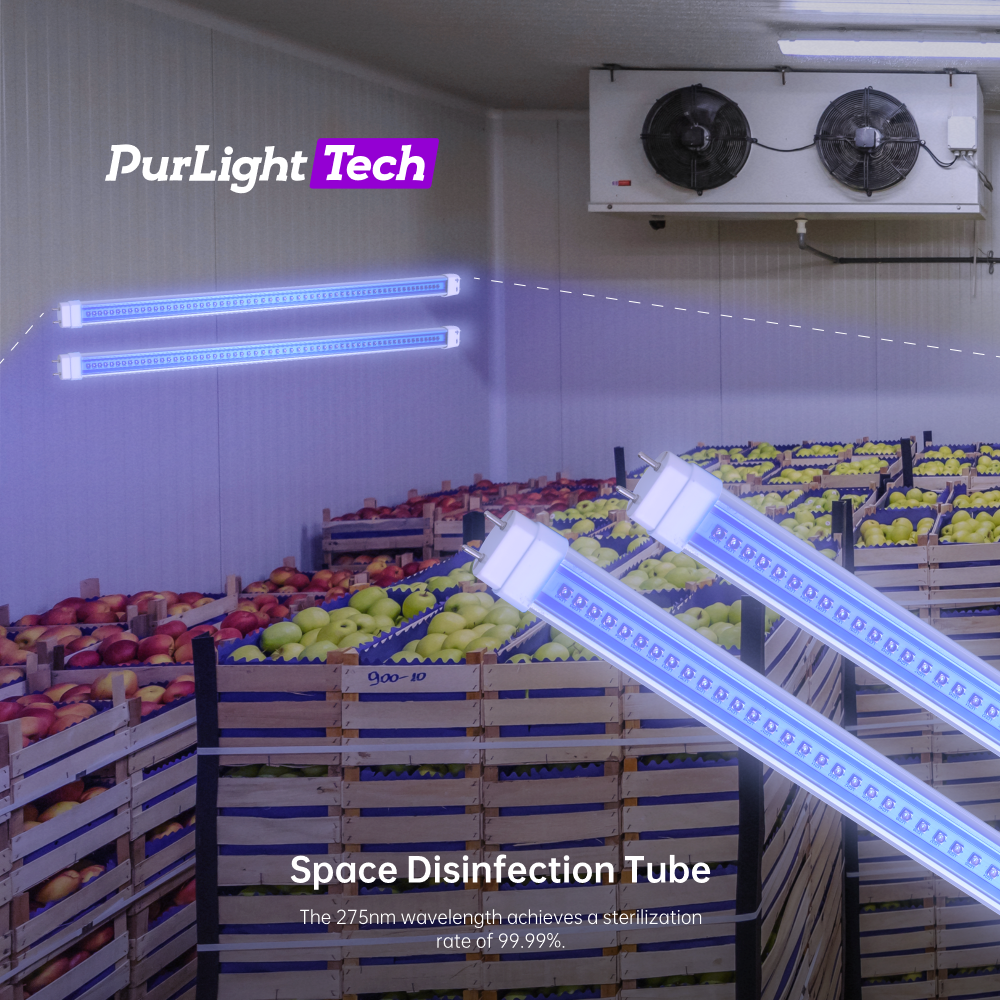

UVC LED 275nm technology has emerged as a revolutionary solution for disinfection and sterilization. This case study explores its applications in food processing facilities and public spaces, highlighting the efficiency, safety, and versatility of this advanced technology.

Maintaining high standards of hygiene and preventing contamination is critical in food processing and public environments. Traditional disinfection methods, such as chemical sprays and mercury-based UV lamps, often come with drawbacks like chemical residue, environmental impact, and high energy consumption. There was a pressing need for a more efficient, sustainable, and safe disinfection solution.

UVC LED 275nm technology offers a powerful and environmentally friendly alternative. This specific wavelength is highly effective in destroying the DNA and RNA of bacteria, viruses, and other pathogens, rendering them harmless. Key advantages include:

Case 1: Food Processing Facility

Implementation:

Results:

Client Testimonial:

"The UVC LED 275nm system has transformed our approach to food safety. We’ve achieved unprecedented levels of cleanliness while reducing operational costs. It’s a win-win for our business and our customers."

—Plant Manager, Food Processing Facility

UVC LED 275nm technology has proven to be a highly effective and sustainable solution for disinfection in both food processing and public environments. Its ability to deliver rapid, chemical-free sterilization while reducing operational costs makes it an ideal choice for industries prioritizing hygiene and safety.

As awareness of UVC LED 275nm benefits grows, its adoption is expected to expand into healthcare, hospitality, and educational institutions. Ongoing advancements in LED efficiency and affordability will further drive its integration into everyday disinfection practices.

Ready to transform your disinfection protocols? Contact us at [email protected]

/(1)213-8814640

to learn how UVC LED 275nm technology can benefit your facility.